The subject of kettle wear is a very important one, and something that is often discussed amongst galvanizing plants and our team here at CIC Pittsburgh. The reason it is so often discussed is that kettle life is a critical factor in the operation of a galvanizing plant. There is ever-present pressure to get as much life (tons) out of the kettle before swapping it out. This is because of not only the great expense (and lead time) of the kettle, but also the downtime associated with the swap (pump-out, cooldown, setting, heat-up, and re-melting). On this matter, we are all aligned in our interests of maximizing the life of the kettle.

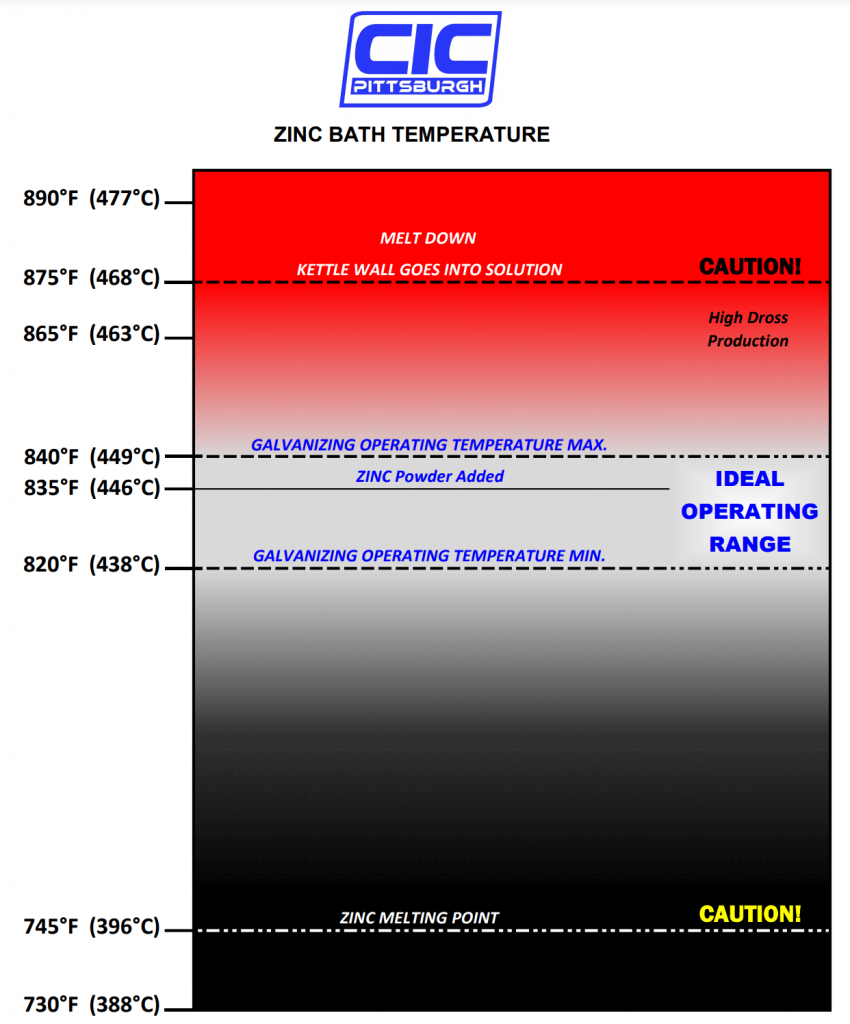

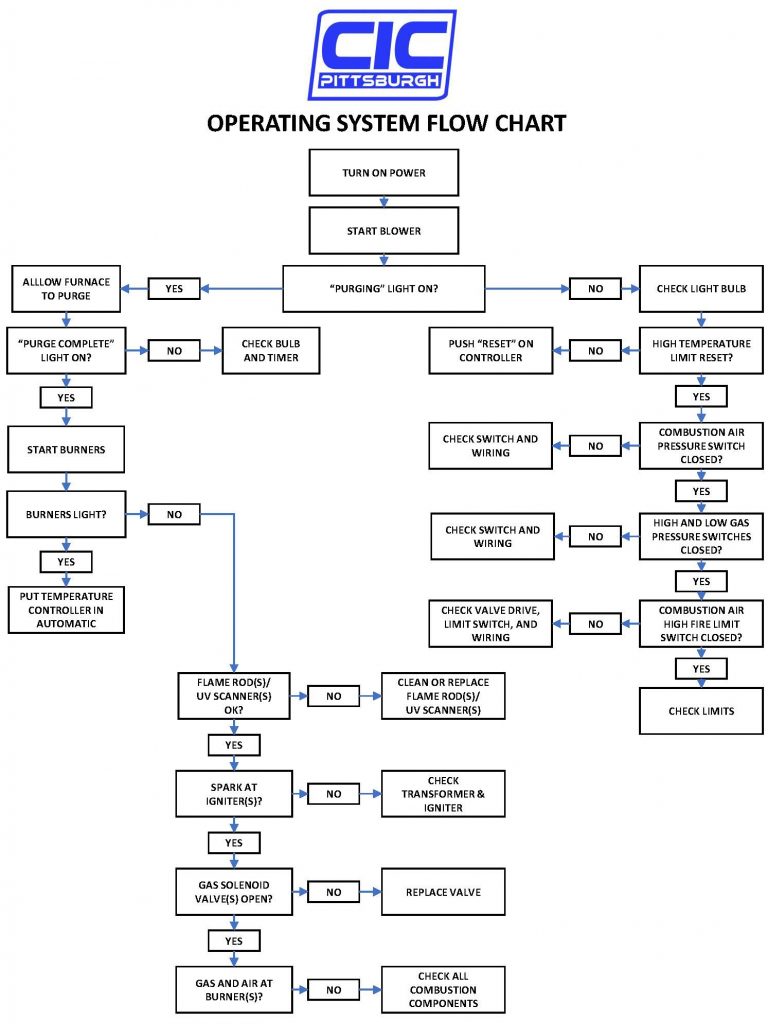

With that said, there are many factors at play that will affect the kettle wear and life, including the operating temperature, number of operating shifts/day, number of hours of production, productivity, and dross collected. However, there are many more factors that would also need to be included in a proper statistical analysis; namely, number of dips, variability in mass/volume of the dips, cleanliness of the steel, pre-flux and other chemical consumption, burner firing times, number of re-starts, and number of temperature excursions. In addition, there are other factors which will influence the kettle life which are not as easily gathered, such as zinc splash intensity, number of and intensity of mechanical impacts of the load on the kettle walls, deterioration of the equipment (insulation, kettle supports, etc.), burner and combustion system tuning and operating characteristics, etc.

Adding to the complexity of the question is that the wear rate will be different on different wall surfaces – top vs. bottom, side wall vs. end wall, base edge vs. vertical edge, near or far from burners, etc. There are services available that can take ultrasonic measurements of the kettle walls. These measurements will be much better than any estimate, but will still leave a high level of question because wear rates are non-linear. So, what things looked like yesterday offers no promise of what things will look like tomorrow.

All of this is to say that there is currently no real precise way to predict the wear rate or ultimate life of the kettle. Under the assumption that within a given plant, the practices between kettles is more or less consistent, we generally defer to the plant’s operating experiences (what have you seen with your other kettles). Beyond that, we have a historical reference frame that suggests a “typical” kettle life will be about 5-7 years – more if the usage is gentle and steady / less if the usage is harsh with many transient conditions.

Further to the point, if you are interested, below is a link to an article on the American Galvanizers Association that was the result of a survey of 37 operations. The presentation, Ways to Extend Kettle Life Service, shows how kettle life varies, but does not list the variability.