20 YEARS OF EXPERIENCE

Galvanizing Industry

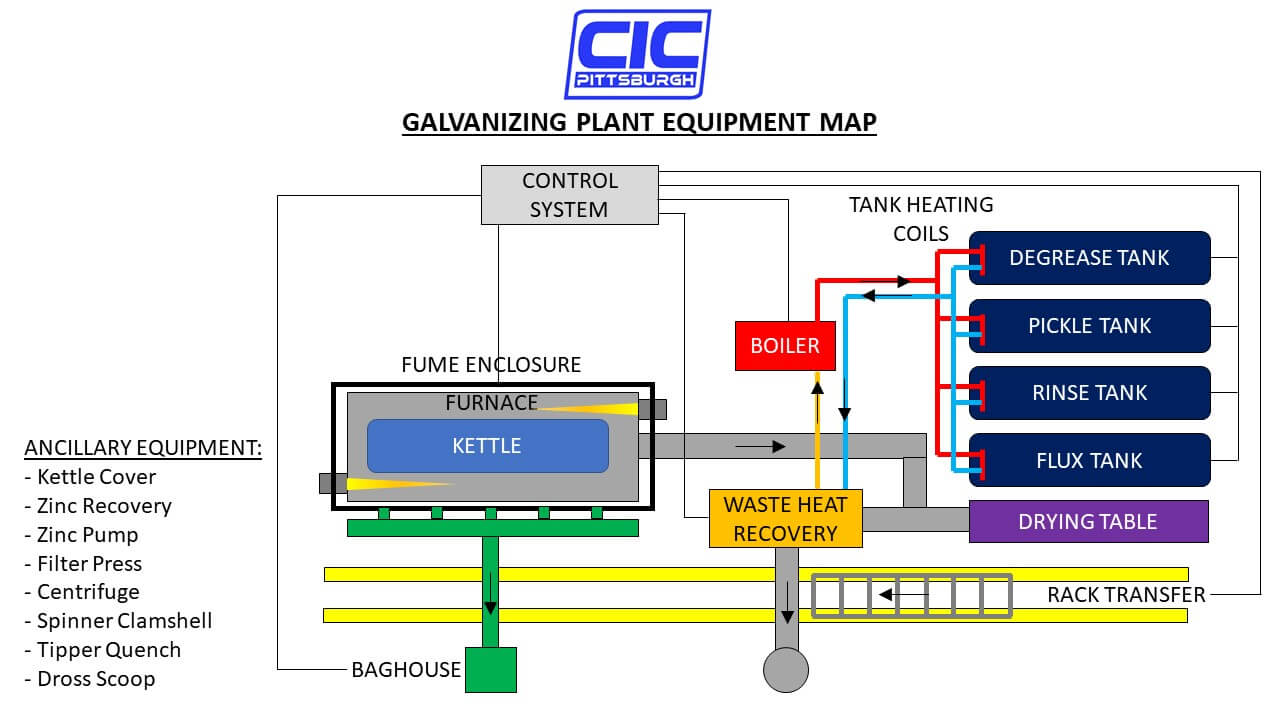

For the hot dip galvanizing industry, CIC Pittsburgh is a leading designer of energy efficient galvanizing furnaces, with the capability to aid in the design of plant layouts to make the most of your valuable work space. CIC Pittsburgh also provides supporting equipment such as rack handling and transfer devices, furnace enclosures and flue gas heat recovery systems.

CIC Pittsburgh is a respected name in the hot dip galvanizing industry. We have 20 years of experience providing galvanizing furnaces and equipment to companies worldwide.

DESIGNING WITH PURPOSE

White Fume Enclosure

White Fume Enclosure